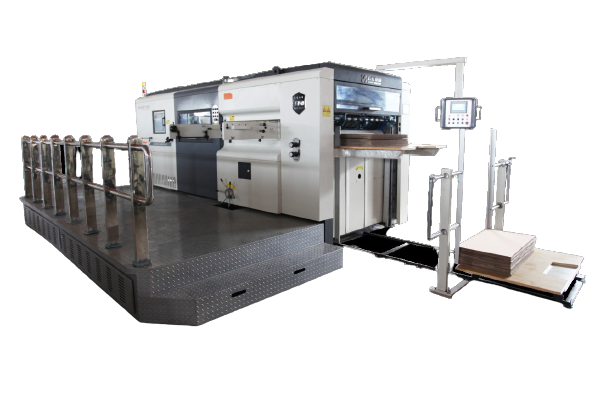

Century MWB 1450Q (ngokuhluba) Semi-Auto Flatbed Die Cutter

| Umzekelo | MWB1450Q |

| Max.Ubungakanani bePhepha | 1480*1080 mm |

| Min.Ubungakanani bePhepha | 550*480 mm |

| Max.Ukusika ubukhulu | 1450*1050 mm |

| Max.Ukusika Uxinzelelo | 300x104N |

| Uluhlu lwesitokhwe | Ibhodi edibeneyo ≤ 9 mm |

| Die Cutting Ukuchaneka | ±0.5 mm |

| Max.Isantya soomatshini | 4000s/h |

| Uhlengahlengiso loxinzelelo | ±1 mm |

| Ubuncinane boMda wangaphambili | 8MM |

| Ubungakanani bokusukelana ngaphakathi | 1480*1080 mm |

| Amandla Aphelele | 21KW (ngaphandle kweqonga lomsebenzi |

| Ubungakanani bomatshini | 7750*4860*2440 mm (Bandakanya iqonga lomsebenzi, i-pre-feeder) MWB1620Q |

| Ubungakanani bomatshini | 5140*2605*2240 mm (Kungabandakanyi iqonga lomsebenzi, i-pre-feeder) MWB1620Q |

| Ubunzima obupheleleyo | 19t |

ICandelo lokutyisa

√Inkqubo esebenzayo yokondla ngesandla.

√Inkqubo yokunyusa imfumba ezenzekelayo.

√Isikhokelo esisecaleni sokubeka iziko lemfumba yephepha.

√Isebenza ku-E, B, C, Flute kunye nodonga oluphindwe kabini.

Die Cutting Icandelo

√I-pneumatic push iqhosha lokugxotha ukuvala indlela yokutshixa ukuqinisekisa ukhuseleko kunye nokutshintsha komsebenzisi kwepleyiti yokusika ukufa.

√Inkqubo yomgca weziko lokusika ngokukhawuleza ukusetha kunye nokutshintsha.

√Inkqubo ye-knuckle yoxinzelelo oluphezulu lokusika ukuya kwiitoni ezingama-400

√I-automatic kunye ne-self-lubrication inkqubo ye-Self-lubrication ukuze usebenze kakuhle kunye nobomi obude

√Umnyango wokhuseleko kunye nesixhobo sombane sombane ukuze usebenze ngokukhuselekileyo.

Icandelo lokukhulula

√Isakhelo sokuhluba saphezulu sinokuphakanyiswa ukuze kuhlulwe ukufakela kunye nokutshintsha.

√Inkqubo ye-Centerline yokuqhawula ngokukhawuleza ukufa kumiswe kunye nokutshintsha umsebenzi

√Isixhobo sokutshixa isakhelo, sibhetyebhetye kwaye kulula ukusitshixa kwaye sikhulule i-striping die.

√I-Photo-sensor kunye nefestile yokhuseleko exhotyiselwe ukusebenza ngokukhuselekileyo.

√Inkqubo yokuhlubula i-semi-stripping ishiya i-edge yokubamba ingakhutshwa.

iCandelo lonikezelo

√Iimbaleki ezisecaleni nangaphambili ukuqinisekisa ukupakishwa kakuhle.

√Inkqubo yokuhanjiswa kwePallet

√Isixhobo somcuphi wefoto sombane wokungena kunye nokusebenza ngokukhuselekileyo.

Icandelo loLawulo loMbane

√I-Siemens PLC l iteknoloji yokuqinisekisa ukubaleka simahla.

√Amacandelo ombane avela kwi-Siemens, eSchneider.

√Onke amacandelo ombane adibana ne-CE standard

| Igama lenxalenye | Uphawu |

| Ukuthwala okuphambili | NSK |

| Main drive chain | RENOLD |

| Inverter rhoqo | YASKAWA |

| Amacandelo oMbane | Siemens / Schneider |

| Umfaki khowudi | OMRON |

| Abenzi boluvo beefoto | Panasonic/Omron |

| Injini engundoqo | Siemens |

| Ilungu le-pneumatic | AirTac/SMC |

| PLC | Siemens |

| Iphaneli yokuchukumisa | Siemens |

Umphakeli wangaphambili

Le pre-feeder inceda ukwenza amaxwebhu alandelayo amfumbe alungele kwaye enze utshintsho olukhawulezayo lwemfumba yamaphepha.Xa umqhubi esondla amaphepha kwi-die cutter, omnye umqhubi unokulungisa enye imfumba yamaphepha ngaxeshanye.Nje ukuba ukondliwa kwamaphepha kugqityiwe, imfumba yashiti elungiselelwe kwi-fieder yangaphambili inokutyhalelwa kwisixhobo sokuphakamisa imfumba esizenzekelayo.Oku kuya konga malunga nemizuzu emi-5 yokulungiselela imfumba yeeshiti nganye kwaye yandise imveliso.

Iphaneli yokusebenza enengalo eshukumayo// Siemens Smart line Touch Panel

ICandelo lokutyisa

√Ikhamera yokuhlola imeko yecandelo lonikezelo ngaphakathi

√Isixokelelwano sokuphakamisa imfumba ngokuzenzekela

√Isixhobo sokulungisa umsantsa phakathi kwamaphepha kunye nezibambi.

√Ifestile yokhuseleko kunye ne-photo-sensor zibonelela ngokhuseleko lomsebenzisi kunye nomatshini xa ifestile yokhuseleko ivuliwe.

√Ukucofa ipleyiti ukuqinisekisa ukuba amashiti akaze atyiswe kakhulu ukuze afe

√Ababalekayo abasecaleni ukugcina imfumba isoloko isembindini kwaye baphumeze lula nangokuchanekileyo amashiti.

Isivamvo sefoto ukugcina imfumba iphakamisa rhoqo ngexesha lokutyisa amashiti.

Die Cutting Icandelo

√Die cut plate yenziwe nge-65Mn ngobulukhuni be-HRC45, ilungele ukusika ukufa.

√Ifestile yokhuseleko ilungiselelwe ukhuseleko lwabasebenzi kunye noomatshini.

√Isistim yomgca wombindi wokusika ngokukhawuleza iseti yokufa kunye nokutshintsha umsebenzi.

√Ukusika isiphatho sohlengahlengiso lwamandla.Kulula kwaye kulula.

Ivili leNtshulube elinezandla zokusila ukuqinisekisa ukuguda komphezulu wokusika okuchanekileyo.

I-automatic self-lubrication system

I-Mono-cast yenzelwe ukungcangcazela okuncinci xa umatshini usebenza.

I-apron yenkxaso inokulungelelaniswa kwiisayizi ezahlukeneyo zobukhulu bamaphepha ahlukeneyo.

iCandelo lonikezelo

√Indlela yokuhanjiswa kwepalethi engayekiyo

√Iphaneli yokusebenza

√Ifestile yokhuseleko

√Isivamvo sefoto sixhotyiselwe ukuqinisekisa ukuba umatshini uya kuyeka xa kukho into engena kumatshini kweli candelo.

√Ababaleka ecaleni baqokelela amashiti acocekileyo

Ukujonga ifestile yokukhangela ingqokelela yamaphepha kwaye wenze uhlengahlengiso oluyimfuneko xa lufuneka.

Isixhobo sohlengahlengiso kwifomathi yephepha

Ulawulo loMbane

CPU Module//Siemens Simatic S7-200

Yaskawa Frequency Inverter

Schneider relays, abafowunelwa njalo njalo.

Imivalo ye-Gripper, eyenziwe ngezinto eziphathekayo ze-aerospace.

Iiseti ezimbini ezongezelelweyo zebar gripper ziya kuthunyelwa kunye nomatshini njengeendawo ezisecaleni.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)