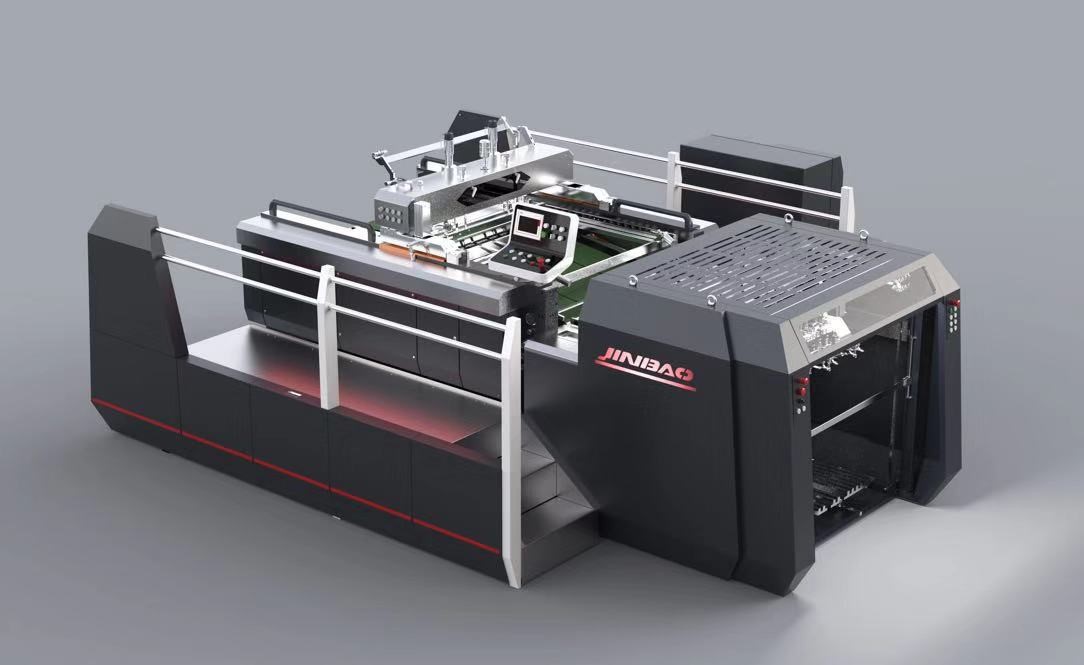

JB-106AS Servo Motor Controlled Automatic Stop Cylinder Screen Press

| JB-106AS | |

| Max.ubungakanani bephepha | 1060×750㎜² |

| Min.ubungakanani bephepha | 560×350㎜²inkonkxa |

| Max.ubungakanani boshicilelo | 1050×750㎜² |

| Ubungakanani besakhelo | 1300×1170 mm² |

| Ukutyeba kweshiti | 80-500 g/m² |

| Umda | ≤10mm |

| Isantya soshicilelo | 800-5000sheet/h |

| Amandla ofakelo | 3P 380V 50Hz 24.3Kw |

| Ubunzima bubonke | 4600㎏ |

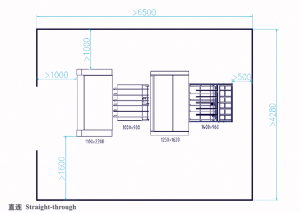

| Ubungakanani bubonke | 4850×4220×2050 mm |

1. Iphepha lokutyisa iphepha: i-offset Feida intloko, isantya esiphezulu, ukuthembeka kunye nokuzinza.

Inokuguquguquka okuqinileyo kubukhulu beendawo eziprintiweyo, kwaye iqinisekisa ukutya kwephepha eligudileyo ngesantya esiphezulu;

I-feeder yephepha inokukhetha ngokwayo kwaye itshintshe ishidi elinye okanye i-laminated paper ngeqhosha elinye.

2. Itafile yokutya ngamaphepha:

Itheyibhile yokutya yamaphepha ensimbi engenasici inokuthintela ngokufanelekileyo umva we-substrate ukuba uhlanjululwe, kwaye unciphise ukuxhatshazwa kwe-static phakathi kwetafile kunye ne-substrate;

Nge-vacuum adsorption ephantsi kwetafile, kunye nesakhiwo sephepha lokutyhala kunye nephepha lokucofa etafileni, ukuqinisekisa ukuthuthwa kakuhle kwezinto ezahlukeneyo;

Xa iphepha elinye lephepha lityiswa, ibhanti yokuhambisa iyancipha ngexesha elifanelekileyo ukuqinisekisa ukuba i-substrate izinzile kwaye isendaweni ngesantya esiphezulu.

3. Igeyiji esecaleni yomoya:

Igeyiji yokutsala yecala lokufunxa ezantsi ayisayi kubangela iphepha elimhlophe nelimdaka namanqaku okubhaliweyo;

Uhlobo olunye lwegeji yegeyiji eguquguqukayo yomzimba, iswitshi enye engundoqo, ukuqala kunye nokulawula i-push gauge pull gauge conversion;

Ukutyhala ukutsalwa kukuchanekile, indawo yokubeka istroke inde, isantya sokumisa siyakhawuleza, kwaye uhlengahlengiso lufanelekile.Inkqubo yokukhangela i-photoelectric inokubeka iliso kwindawo yeengxenye eziprintiweyo ngexesha langempela kunye nokunciphisa izinga lokushicilela inkunkuma.

4. Inkqubo engenamphini: umthombo wamandla omnye wemveli wedrive ephambili eneendlela ezininzi zokuqhuba

Ukusebenzisa itekhnoloji yokuqhuba i-synchronous, i-shaft yothumelo, i-gearbox kunye nezinye izixhobo zoomatshini ziyasuswa, kwaye iimotor ezininzi ze-servo zisetyenziselwa ukulandela i-electron spindle ebonakalayo.Inani elikhulu lamalungu othungelwano ngoomatshini aphelisiwe.

Ukunciphisa ingxolo: i-shaft engundoqo yemveli kunye nebhokisi yegiya ilahliwe, iindawo ezihambayo ziyancitshiswa, ubume bomatshini benziwa lula, kwaye izinto ezivelisa ukungcangcazela koomatshini ziyancitshiswa, ngoko ke ingxolo iyancipha kakhulu kwinkqubo yokusebenza.

5. Inkqubo yokucoca i-pneumatic enzima: ukusetyenziswa okubanzi kombane, i-pneumatic, iteknoloji ye-hydraulic, ukulawulwa ngokuzenzekelayo kwesenzo sokukrala;

Amanqaku okuqala kunye nokuphela angamiselwa ngokuzimeleyo;

Uxinzelelo lwenkqubo yonke lunokulinganisela kwaye luzinzile;

Emva kokugaya i-scraper okanye ukuyibuyisela entsha, cinezela iqhosha elinye ukuseta nokubuyisela indawo yoxinzelelo lwangaphambili lokushicilela;

Iphelisa ngokupheleleyo ukungalungi kwe-cam mechanical control of squeegee action, kwaye iqinisekisa ukuba umaleko we-inki kunye nokucaca komfanekiso uzinzile phantsi kwawo nawuphi na umthamo wokushicilela kunye nesantya sokushicilela.

6. Umsebenzi wokwahlula isikrini:

Isikrini sihlukaniswe ngokulawulwa kombane ukuveza yonke itafile yokuhambisa kunye ne-roller, ukwenzela ukuba kube lula ukubhaliswa kwamacandelo okushicilela kunye nokulungiswa kwezinto zokutya;ngelo xesha, ukucocwa kwe-roller kunye nesikrini kukhuselekile kwaye ngokukhawuleza;

7. Inkqubo yokucoca isikrini sombane, isikrini sombane esikude uhlengahlengiso lwe-axis ezintathu, i-stroke yokulungelelanisa igalelo ngqo, ukulungiswa kwesinyathelo esinye endaweni, kulungele kwaye kusebenza.

8. I-oiling ngokuzenzekelayo kunye nenkqubo yokuthambisa inokunciphisa ukutsalwa kwekhonkco kunye nengxolo, kwaye iqinisekise ukuchaneka komsebenzi kunye nokuzinza.

| Into | Umyalelo | |||

| 1 | Umondli |

| ||

|

| ● | Ngasemva pick up offset version feeder intloko | Ezine zifunxa unikezelo ezine, kunye nokulungiswa kwangaphambili kwindawo | umgangatho |

| ● | Imowudi kabini yokutyisa iphepha | Iphepha elinye (isantya sokutya kwephepha eliguquguqukayo) okanye ukugqithelana (ukutya kwephepha elilinganayo elilinganayo) | umgangatho | |

| ● | Ukutshintsha ngokukhawuleza kwendlela yokutya yephepha | isitshixo esinye sokutshintsha | umgangatho | |

| ● | Ukufunyanwa kombane ophindwe kabini | umgangatho | ||

| ● | Ukufunyanwa kwephepha eliphindwe kabini le-ultrasonic | ingasetyenziselwa kuphela indlela yokutyisa iphepha elinye | ngokuzikhethela | |

| ● | Iqhosha elinye lokutshintsha ubungakanani bephepha | intloko feeder kunye necala gauge stop iphepha kwindawo ngokukhawuleza kwaye ngokuzenzekelayo | umgangatho | |

| ● | Ukhuseleko lulinganiselwe ekuphakamiseni umxhesho | umgangatho | ||

| ● | Ubumbeko olusemgangathweni lwenkqubo engayekiyo | umgangatho | ||

| ● | Ukulayisha kwangaphambili | qokelela izixhobo zokuprinta kwangaphambili, ukunciphisa ixesha lokupakisha kunye nokuphucula ukusebenza kakuhle | ngokuzikhethela | |

| ● | Isixhobo sokuphelisa umbane esingatshintshiyo | inokunciphisa umbane ongatshintshiyo kwindawo yezinto kunye nokuphucula umphumo wokushicilela | ngokuzikhethela | |

| ● | ukufunyanwa kwe-photoelectric yokunqongophala kwephepha letafile yokutyisa iphepha | umgangatho | ||

| 2 | Ukuhanjiswa kwephepha kunye nokulungelelaniswa kwangaphambili-ukulala kunye nokulala kwecala |

| ||

|

| ● | inkqubo yokuhambisa iphepha nge vacuum | umgangatho | |

| ● | icala eliphindwe kabini ukuya ezantsi igeyiji yokutsala umoya yokufunxa | ukuphepha ukutsalwa kwephepha ngaphambili. | Umgangatho | |

| ● | Igeyiji yokutyhala emacala amabini | iphepha elishinyeneyo loshicilelo | Umgangatho | |

| ● | tsala igeyiji / iqhosha lokutyhala | isitshixo esinye | Umgangatho | |

| ● | iphepha kwindawo yokubona umbane | Igeyiji yecala ekubhaqweni kwendawo kunye negeji yangaphambili ekubhaqweni kwendawo | Umgangatho | |

| ● | Iqhosha elinye lokutshintsha ubungakanani bephepha;iqhosha elinye lokuseta kwangaphambili | side gauge / feed ibhrashi ivili ngokukhawuleza kwaye ngokuzenzekelayo endaweni | Umgangatho | |

| 3 | Isilinda sokushicilela |

| ||

|

| ● | Uhlobo lwesakhelo isakhiwo se-roller esilula | Inertia encinci, ukusebenza okuzinzileyo | Umgangatho |

| ● | i-adsorption yoshicilelo kunye nokuvuthela isixhobo sokuqhawula | Umgangatho | ||

| ● | isixhobo anti rebound yephepha elishinyeneyo | Umgangatho | ||

| 4 | Isakhelo sokuPrinta |

| ||

|

| ● | Indlela ezintathu zombane kwiscreen uhlengahlengiso olulungileyo | Uhlengahlengiso lweendlela ezintathu zesikrini sombane esikude | Umgangatho |

| ● | Ulungelelwaniso lwepleyiti yoshicilelo engayekiyo ethe nkqo | Umgangatho | ||

| ● | imbuyekezo oluzenzekelayo ngobude bokushicilela ukushwabana kunye nokwandiswa | Imbuyekezo ezenzekelayo yokutshintsha ubude bephepha obubangelwa yinkqubo yangaphambili yokushicilela | Umgangatho | |

| ● | isixhobo sokutshixa se-pneumatic | Umgangatho | ||

| ● | isakhelo sihamba ngokuzimeleyo kwaye sikhupha kwisixhobo | Umgangatho | ||

| 5 | Inkqubo yemela yokushicilela ipneumatic |

| ||

|

| ● | Uxinzelelo oluzenzekelayo oluqhubekayo kunye nokulungelelaniswa ngokuzenzekelayo kwemela yokushicilela | Gcina uxinzelelo lokushicilela rhoqo kwaye uphucule umgangatho wokushicilela | Umgangatho |

| ● | Ukubambelela ngokukhawuleza nangokuzenzekelayo kwemela yokuprinta kunye nemela yokubuyisela i-inki | I-clamping force ye-printing imela ilinganayo, ekulungele ukubuyisela imela yokushicilela (i-squeegee) | Umgangatho | |

| ● | ukuphakamisa nokuhla okukrelekrele | Ngokwemiqathango yoshicilelo, misela indawo yemela / imela, ukwandisa ubomi berabha yokukrala kunye nomnatha, kwaye unciphise inkunkuma yeinki. | Umgangatho | |

| ● | isixhobo sokulahla inki | Umgangatho | ||

| 6 | Abanye |

| ||

|

| ● | inkqubo yokuphakamisa i-pneumatic yebhodi yephepha | Umgangatho | |

| ● | inkqubo yokuthambisa oluzenzekelayo | Umgangatho | ||

| ● | isikrini sokulawula umatshini womntu | Umgangatho | ||

| ● | ukhuselo lokhuseleko grating | Ukwandisa into yokhuseleko ukuqinisekisa ukhuseleko lomntu lwabaqhubi | ukhetho | |

| ● | unogada wokhuseleko | Ukwandisa into yokhuseleko kunye nokunciphisa impembelelo yothuli kuShicilelo | ukhetho | |