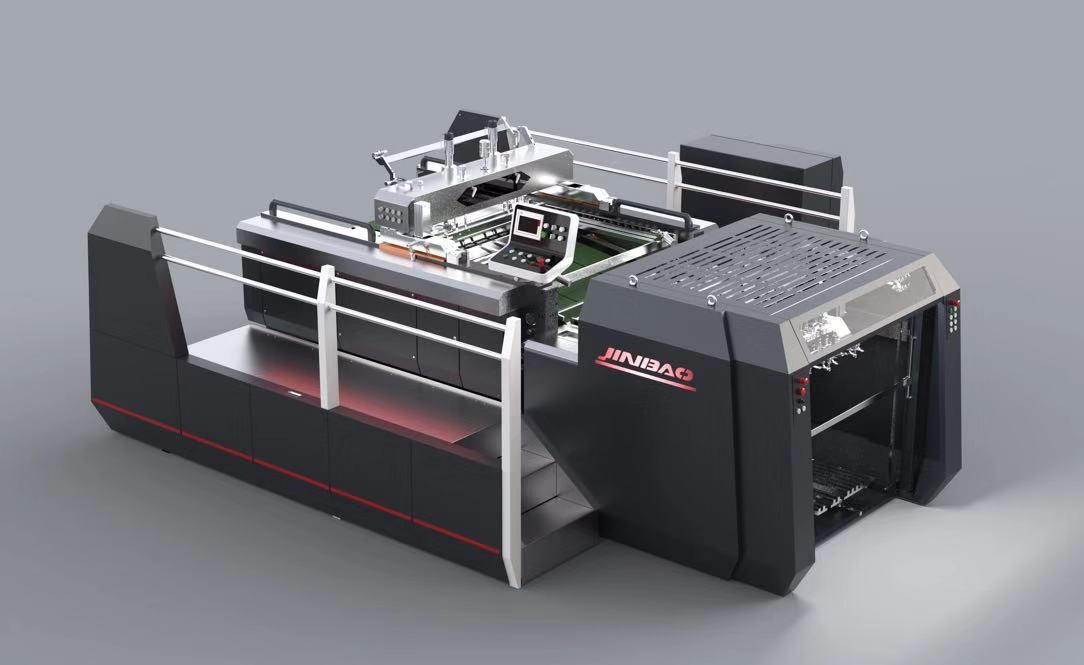

I-JB-145AS i-Servo Motor Controlled Automatic Stop Cylinder Screen-Printing Machine

Luhlobo olutsha lomatshini wokushicilela wesikrini okrelekrele ophuhliswe ngokuzimeleyo kwaye uyilwe yinkampani yethu enamalungelo azimeleyo epropathi yengqondo. Inamalungelo awodwa omenzi wokuqanjwa amathathu kunye neepatent ezintlanu zemodeli eluncedo. Isantya soshicilelo olupheleleyo sinokuya kuma-3000 amaqhekeza / iyure phantsi kwemfuneko yokuqinisekisa umgangatho weemveliso zokuprinta. Lolona khetho lulungileyo lokupakishwa kwephepha kunye neplastiki, i-ceramic kunye ne-cellophane, ukuhanjiswa kwelaphu, iimpawu zetsimbi, utshintsho lwefilimu yeplastiki, izinto zombane kunye nombane kunye namanye amashishini.

Umatshini ushiya ishaft yomthombo wamandla omnye webhanti, ibhokisi yegiya kunye nemowudi yekhonkco, usebenzisa ii-servo motors ezininzi ukuqhuba i-feeder, ukuhambisa, i-roller kunye nesakhelo se-mesh ngokulandelelana, iqinisekisa ulungelelwaniso lweeyunithi ezininzi ezisebenzayo ngolawulo oluzenzekelayo, hayi kuphela ukuphelisa inani elikhulu. yamacandelo othumelo ngoomatshini, kodwa ikwaphucula kakhulu ubungqongqo koomatshini bokuprinta, kwaye kunciphisa iimpazamo ezibangelwa sisixhobo sothumelo ngoomatshini. umgangatho wokushicilela kunye nokusebenza kakuhle komatshini, ukuphucula umgangatho wokuzenzekelayo wenkqubo yokuvelisa, ukuphucula iimeko zokusebenza zokusingqongileyo.

|

| JB-145AS |

| Ubukhulu beshiti | 1460×1060㎜² |

| Ubuncinci bephepha | 700×460㎜² |

| Max.ubungakanani boshicilelo | 1450×1050㎜² |

| Ubungakanani besakhelo | 1720×1450 mm² |

| Ukutyeba kweshiti | 108-420 g/m² |

| Umda |

|

| Isantya soshicilelo | 400-3000sheet/h |

| Amandla ofakelo | 3P 380V 50Hz 25.83Kw |

| Ubunzima bubonke | Malunga nama-6500㎏ |

| Ubungakanani bubonke | 5300×4000×2090㎜³ |

1. Iphepha lokutyisa iphepha: i-offset Intloko ye-Feeder, isantya esiphezulu, ukuthembeka kunye nokuzinza.

Inokuguquguquka okuqinileyo kubukhulu beendawo eziprintiweyo, kwaye iqinisekisa ukutya kwephepha eligudileyo ngesantya esiphezulu;

I-feeder yephepha inokukhetha ngokwayo kwaye itshintshe ishidi elinye okanye i-laminated paper ngeqhosha elinye.

2. Itafile yokutya ngamaphepha:

Itheyibhile yokutya yamaphepha ensimbi engenasici inokuthintela ngokufanelekileyo umva we-substrate ukuba uhlanjululwe, kwaye unciphise ukuxhatshazwa kwe-static phakathi kwetafile kunye ne-substrate;

Nge-vacuum adsorption ephantsi kwetafile, kunye nesakhiwo sephepha lokutyhala kunye nephepha lokucofa etafileni, ukuqinisekisa ukuthuthwa kakuhle kwezinto ezahlukeneyo;

Xa iphepha elinye lephepha lityiswa, ibhanti yokuhambisa iyancipha ngexesha elifanelekileyo ukuqinisekisa ukuba i-substrate izinzile kwaye isendaweni ngesantya esiphezulu.

3. Igeyiji esecaleni yomoya:

Igeyiji yokutsala yecala lokufunxa ezantsi ayizukubangela iphepha elimhlophe nelimdaka namanqaku okubhaliweyo.

Uhlobo olunye lwegeji yokulinganisa umzimba, iswitshi enye, ukuqala kunye nokulawula ukuguqulwa kwegeji yokutyhala.

I-Push pull positioning ichanekile, i-stroke yokubeka inde, isantya sokumisa siyakhawuleza, kwaye uhlengahlengiso lufanelekile. Inkqubo yokukhangela i-photoelectric inokubeka iliso kwindawo yeendawo eziprintiweyo ngexesha langempela kunye nokunciphisa izinga lokushicilela inkunkuma.

4. Inkqubo engenamphini: umthombo wamandla omnye wemveli wedrive ephambili eneendlela ezininzi zokuqhuba

Ukusebenzisa itekhnoloji yokuqhuba i-synchronous, i-shaft yothumelo, i-gearbox kunye nezinye izixhobo zoomatshini ziyasuswa, kwaye iimotor ezininzi ze-servo zisetyenziselwa ukulandela i-electron spindle ebonakalayo. Inani elikhulu lamalungu othungelwano ngoomatshini aphelisiwe.

Unciphiso lwengxolo: ishaft yemveli kunye nebhokisi yegiya ilahliwe, iindawo ezihambayo ziyancitshiswa, ubume bomatshini benziwa lula, kwaye izinto ezivelisa ukungcangcazela koomatshini ziyancitshiswa, ngoko ke ingxolo iyancipha kakhulu kwinkqubo yokusebenza.

5. Inkqubo yokucoca i-pneumatic enzima: ukusetyenziswa okubanzi kombane, i-pneumatic, iteknoloji ye-hydraulic, ukulawulwa ngokuzenzekelayo kwesenzo sokukrala;

Amanqaku okuqala kunye nokuphela angamiselwa ngokuzimeleyo.

Uxinzelelo lwenkqubo yonke lunokulinganisela kwaye luzinzile.

Emva kokugaya i-scraper okanye ukuyibuyisela entsha, cinezela iqhosha elinye ukuseta kunye nokubuyisela indawo yoxinzelelo lwangaphambili lokushicilela.

Iphelisa ngokupheleleyo ukungalungi kwe-cam mechanical control of squeegee action kwaye iqinisekisa ukuba i-inki ye-inki kunye nokucaca komfanekiso uzinzile phantsi kwawo nawuphi na umthamo wokushicilela kunye nesantya sokushicilela.

6. Umsebenzi wokwahlula isikrini:

Isikrini sihlukaniswe ngolawulo lombane ukuveza yonke itafile yokuhambisa kunye ne-roller, ukwenzela ukuba kube lula ukubhaliswa kwamacandelo okushicilela kunye nokulungiswa kwezinto zokutya; ngexesha elifanayo, ukucocwa kwe-roller kunye nesikrini kukhuselekile kwaye ngokukhawuleza.

7. Inkqubo yokucoca isikrini sombane, isikrini sombane esikude uhlengahlengiso lwe-axis ezintathu, i-stroke yokulungelelanisa igalelo elichanekileyo, ukulungiswa kwesinyathelo esinye endaweni, kulungele kwaye kusebenza.

8. I-oiling ngokuzenzekelayo kunye nenkqubo yokuthambisa inokunciphisa ukutsalwa kwekhonkco kunye nengxolo, kwaye iqinisekise ukuchaneka komsebenzi kunye nokuzinza.

Iseti yokususa ngokuzenzekelayo yokushicilela kwesikrini kunye ne-semi-automatic screen printing press zisetyenziswa kunye, iimveliso ezigqityiweyo ziyabanjwa kwaye zikhutshwe kwipleyiti yokushicilela nge-manipulator kunye nomlomo wokufunxa, kunye nokuhanjiswa kwinkqubo elandelayo (ukomisa, ukuqinisa okanye ukuqokelela) .Ayinakugcina kuphela abasebenzi, kodwa iphucula ukusetyenziswa kakuhle komatshini we-semi-automatic. Ilungele ukuprintwa kwesikrini ngezinto ezithambileyo, njengephepha.

| Into | Umyalelo | |||

| 1 | Umondli |

| ||

|

| ● | Ngasemva pick up offset version feeder intloko | Ezine zifunxa unikezelo ezine, kunye nokulungiswa kwangaphambili kwindawo | umgangatho |

| ● | Imowudi kabini yokutyisa iphepha | Iphepha elinye (isantya sokutya kwephepha eliguquguqukayo) okanye ukugqithelana (ukutya kwephepha elilinganayo elilinganayo) | umgangatho | |

| ● | Ukutshintsha ngokukhawuleza kwendlela yokutya yephepha | isitshixo esinye sokutshintsha | umgangatho | |

| ● | Ukufunyanwa kombane ophindwe kabini | umgangatho | ||

| ● | Ukufunyanwa kwephepha eliphindwe kabini le-ultrasonic | ingasetyenziselwa kuphela indlela yokutyisa iphepha elinye | ngokuzikhethela | |

| ● | Iqhosha elinye lokutshintsha ubungakanani bephepha | intloko feeder kunye necala Guange stop iphepha kwindawo ngokukhawuleza kwaye ngokuzenzekelayo | umgangatho | |

| ● | Ukhuseleko lulinganiselwe ekuphakamiseni umxhesho | umgangatho | ||

| ● | Ubumbeko olusemgangathweni lwenkqubo engayekiyo | umgangatho | ||

| ● | Ukulayisha kwangaphambili | qokelela izixhobo zokuprinta kwangaphambili, ukunciphisa ixesha lokupakisha kunye nokuphucula ukusebenza kakuhle | ngokuzikhethela | |

| ● | Isixhobo sokuphelisa umbane esingatshintshiyo | inokunciphisa umbane ongatshintshiyo kwindawo yezinto kunye nokuphucula umphumo wokushicilela | ngokuzikhethela | |

| ● | ukufunyanwa kwe-photoelectric yokunqongophala kwephepha letafile yokutyisa iphepha | umgangatho | ||

| 2 | Ukuhanjiswa kwephepha kunye nokulungelelaniswa kwangaphambili-ukulala kunye nokulala kwecala |

| ||

|

| ● | inkqubo yokuhambisa iphepha nge vacuum | umgangatho | |

| ● | icala eliphindwe kabini ukuya ezantsi igeyiji yokutsala umoya yokufunxa | ukuphepha ukutsalwa kwephepha ngaphambili. | Umgangatho | |

| ● | Igeyiji yokutyhala emacala amabini | iphepha elishinyeneyo loshicilelo | Umgangatho | |

| ● | tsala igeji / iqhosha lokutyhala | isitshixo esinye | Umgangatho | |

| ● | iphepha kwindawo yokubona umbane | Igeyiji yecala ekubhaqweni kwendawo kunye negeji yangaphambili ekubhaqweni kwendawo | Umgangatho | |

| ● | Iqhosha elinye lokutshintsha ubungakanani bephepha; iqhosha elinye lokuseta kwangaphambili | side gauge / feed ibhrashi ivili ngokukhawuleza kwaye ngokuzenzekelayo endaweni | Umgangatho | |

| 3 | Isilinda sokushicilela |

| ||

|

| ● | Uhlobo lwesakhelo isakhiwo se-roller esilula | Inertia encinci, ukusebenza okuzinzileyo | Umgangatho |

| ● | i-adsorption yoshicilelo kunye nokuvuthela isixhobo sokuqhawula | Umgangatho | ||

| ● | isixhobo anti rebound yephepha elishinyeneyo | Umgangatho | ||

| 4 | Isakhelo sokuPrinta |

| ||

|

| ● | Indlela ezintathu zombane kwiscreen uhlengahlengiso olulungileyo | Uhlengahlengiso lweendlela ezintathu zesikrini sombane esikude | Umgangatho |

| ● | Ulungelelwaniso lwepleyiti yoshicilelo engayekiyo ethe nkqo | Umgangatho | ||

| ● | imbuyekezo oluzenzekelayo ngobude bokushicilela ukushwabana kunye nokwandiswa | Imbuyekezo ezenzekelayo yokutshintsha ubude bephepha obubangelwa yinkqubo yangaphambili yokushicilela | Umgangatho | |

| ● | isixhobo sokutshixa se-pneumatic | Umgangatho | ||

| ● | isakhelo sihamba ngokuzimeleyo kwaye sikhupha kwisixhobo | Umgangatho | ||

| 5 | Inkqubo yemela yokushicilela ipneumatic |

| ||

|

| ● | Uxinzelelo oluzenzekelayo oluqhubekayo kunye nokulungelelaniswa ngokuzenzekelayo kwemela yokushicilela | Gcina uxinzelelo lokushicilela rhoqo kwaye uphucule umgangatho wokushicilela | Umgangatho |

| ● | Ukubambelela ngokukhawuleza nangokuzenzekelayo kwemela yokuprinta kunye nemela yokubuyisela i-inki | I-clamping force ye-printing imela ilinganayo, ekulungele ukubuyisela imela yokushicilela (i-squeegee) | Umgangatho | |

| ● | ukuphakamisa nokuhla okukrelekrele | Ngokwemiqathango yoshicilelo, misela indawo yemela / imela, ukwandisa ubomi be-rubber scraper kunye ne-mesh, kwaye unciphise inkunkuma ye-inki. | Umgangatho | |

| ● | isixhobo sokulahla inki | Umgangatho | ||

| 6 | Abanye |

| ||

|

| ● | inkqubo yokuphakamisa i-pneumatic yebhodi yephepha | Umgangatho | |

| ● | inkqubo yokuthambisa oluzenzekelayo | Umgangatho | ||

| ● | isikrini sokulawula umatshini womntu | Umgangatho | ||

| ● | ukhuseleko lwegrating yokhuseleko | Ukwandisa into yokhuseleko ukuqinisekisa ukhuseleko lomntu lwabaqhubi | ngokuzikhethela | |

| ● | unogada wokhuseleko | Ukwandisa into yokhuseleko kunye nokunciphisa impembelelo yothuli kuShicilelo | ngokuzikhethela | |

|

| ● | Unikezelo lwe-inki oluzenzekelayo | Ukubonelela nge-inki ngokuzenzekelayo | ngokuzikhethela |

| Hayi. | Into | Qty | Uphawu | Phawula |

| 1 | I-feeder drive servo motor | 1 | Baumueller | Jemani |

| 2 | Isondlo esihambisa i-servo motor | 1 | Baumueller | Jemani |

| 3 | Isakhelo drive servo motor | 1 | Baumueller | Jemani |

| 4 | Isilinda drive servo motor | 1 | Baumueller | Jemani |

| 5 | Imotor ephambili yokuphakamisa i-Feeder | 1 | CHENGBANG | China Taiwan |

| 6 | Imotor encedisayo yokuphakamisa i-Feeder | 1 | CHENGBANG | China Taiwan |

| 7 | Impompo edityanisiweyo yesondlo sephepha | 1 | BECKER | Jemani |

| 8 | Ifeni yokondla ngephepha | 1 | I-LINGGE | China Zhejiang |

| 9 | Ifeni yokukhupha iphepha | 1 | I-LINGGE | China Zhejiang |

| 10 | Imveliso yokuhambisa injini | 1 | CHENGBANG | China Taiwan |

| 11 | Intloko yemela yokuprinta imotor yokulungisa kakuhle | 2 | Dunkermotoren | Jemani |

| 12 | Tsala igeyiji / isikrini se-stepper motor | 3 | MBYS | China Shenzhen |

| 13 | Imotor elawula ukunyathela | 4 | MBYS | China Shenzhen |

| 14 | Isilawuli esishukumayo (PLC) | 1 | Baumueller | Jemani |

| 15 | Imodyuli yokwandisa isilawuli | 18 | Baumueller | Jemani |

| 16 | Imodyuli yepharamitha yeServo | 3 | Baumueller | Jemani |

| 17 | Unikezelo lwamandla / isihluzi / imodyuli yokusabela | Enye nganye | Baumueller | Jemani |

| 18 | Imveliso yephepha ehambisa isiguquli samaza | 1 | Mitsubishi | Japhan |

| 19 | Isikrini esibanjwayo | 1 | OMRON | Japhan |

| 20 | Umnxibelelanisi we-AC | 9 | Eaton Muller | Jemani |

| 21 | Umkhuseli weemoto | 5 | Eaton Muller | Jemani |

| 22 | Umephuli wojikelezo | 4 | Eaton Muller | Jemani |

| 23 | Cofa / iqhosha lokutshintshela | 58 | Eaton Muller | Jemani |

| 24 | Ulayisho oluncinci lwelotus | 13 | Fender | ElamaTaliyane |

| 25 | I-Micro relay | 6 | Fender | ElamaTaliyane |

| 26 | inzwa yefiber optical | 8 | OMRON | Japhan |

| 27 | Utshintsho lokungeniswa | 12 | OMRON | Japhan |

| 28 | Utshintsho lokungeniswa | 8 | IFM | Jemani |

| 29 | Ivalve yeSolenoid | 7 | Foster | Jemani |

| 30 | Isilinda | 6 | Foster | Jemani |

| 31 | Isilinda | 12 | SMC | Japhan |

| 32 | Ivalve yeSolenoid | 9 | SMC | Japhan |

| 33 | Impompo yeAutolube | 1 | SHENGXIANG | China Tongxiang |

| 34 | Isikhokelo soshicilelo / isilayidi | 3iseti | THK | Japhan |