I-RB420B i-Automatic Rigid Box Menzi

| I-RB420B Umenzi webhokisi oqinileyo ozenzekelayo | |||

| 1 | Ubungakanani bephepha(A×B) | Amin | 100mm |

| Amax | 580mm | ||

| Bmin | 200mm | ||

| Bmax | 800mm | ||

| 2 | Ubukhulu bephepha | 100-200g / m2 | |

| 3 | Ubunzima bekhadibhodi(T) | 0.8~3mm | |

| 4 | Imveliso egqityiweyo (ibhokisi) ubukhulu(L×W×H) | L×W Umz | 100×50mm |

| L×W Max | 420×320mm | ||

| H Min. | 12 | ||

| H Max. | 120mm | ||

| 5 | Ubungakanani bephepha elisongiweyo (R) | Rmin | 10mm |

| Rmax | 35mm | ||

| 6 | Ukuchaneka | ±0.50mm | |

| 7 | Isantya sokuvelisa | ≦28sheets/min | |

| 8 | Amandla emoto | 8kw/380v 3 isigaba | |

| 9 | Amandla okufudumala | 6kw | |

| 10 | Ubonelelo loMoya | 10L/min 0.6Mpa | |

| 11 | Ubunzima bomatshini | 2900kg | |

| 12 | Ubungakanani bomatshini | L7000×W4100×H2500mm | |

1. Ubukhulu kunye neesayizi ezincinci zeebhokisi zixhomekeke kwezo zephepha kunye nomgangatho wephepha.

2. Umthamo wokuvelisa iibhokisi ze-28 ngomzuzu. Kodwa isantya somatshini sixhomekeke kubungakanani beebhokisi.

3. Asiboneleli ngecompressor yomoya.

Ubudlelwane obuhambelanayo phakathi kweeparamitha:

W+2H-4T≤C(Ubukhulu) L+2H-4T≤D(Ubukhulu)

A(Min)≤W+2H+2T+2R≤A(Ubukhulu) B(Min)≤L+2H+2T+2R≤B(Ubukhulu)

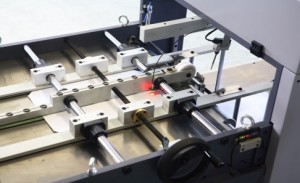

1. I-feeder kulo matshini ithatha inkqubo yokutya i-back-push, elawulwa nge-pneumatically, kwaye isakhiwo sayo silula kwaye sinengqiqo.

2. Ububanzi phakathi kwe-stacker kunye netafile yokutya kulungelelaniswa ngokuthe ngqo kwiziko. Ukusebenza kulula kakhulu ngaphandle kokunyamezela.

3. I-scraper entsha eyenzelwe i-copper isebenzisana ne-roller ngakumbi, iphephe ngokufanelekileyo ukujikeleza kwephepha. Kwaye i-copper scraper yomelele ngakumbi.

4. I-Adopt ye-ultrasonic evela kumazwe angaphandle i-double tester yephepha, ebonisa ukusebenza okulula, okunokugcina amaphepha amabini angangeni kumatshini ngexesha elinye.

5. Ukujikeleza ngokuzenzekelayo, ukuxuba kunye nenkqubo ye-gluing yeglue eshushu. (Isixhobo esinokuzikhethela: imitha yeglue viscosity)

6. Iteyiphu yephepha elinyibilikayo elishushu elihambisa ngokuzenzekelayo, ukusika, kunye nokugqiba ukuncamathelisa ibhokisi yangaphakathi ye-quad stayer (ii-angles ezine) zekhadibhodi kwinkqubo enye.

7. Ifeni yokufunxa ivacuum phantsi kwebhanti yokuhambisa inokugcina iphepha lingaphambuki.

8. Iphepha kunye nekhadibhodi ibhokisi yangaphakathi isebenzisa isixhobo sokulungisa okwenziwa ngoxinzelelo olukhulu olwenziwa ngamanzi aphantsi komhlaba ukuze kubonwe ngokuchanekileyo.

9. I-wrapper inokuqhubeka isonga, isonge iindlebe kunye namacala ephepha kwaye ifake kwinkqubo enye.

10. Umatshini wonke usebenzisa i-PLC, inkqubo yokulandelela i-photoelectric kunye ne-HMI ukwenza ngokuzenzekelayo iibhokisi kwinkqubo enye.

11. Iyakwazi ukuxilonga ngokuzenzekelayo iingxaki kunye ne-alamu ngokufanelekileyo.