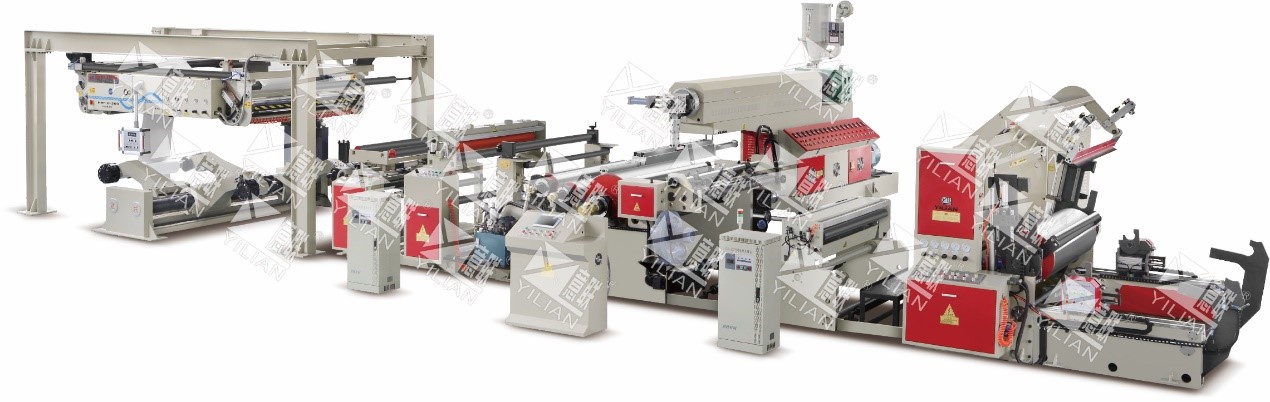

I-WSFM1300C i-Automatic Paper PE Extrusion Coating Machine

| Suit laminating resin | I-LDPE, PP njl |

| Isiseko semathiriyeli | iphepha (80-400g/m²) |

| Isantya esiphezulu soomatshini | 300m/min(isantya sokusebenza sixhomekeke kubunzima bokugquma, ububanzi) |

| Ububanzi bokugquma | 600-1200, isikhokelo roller ububanzi: 1300mm |

| Ubunzima bokugquma | 0.008—0.05mm (Isikrufu esinye) |

| Impazamo yobukhulu bokugquma | ≤±5% |

| Uluhlu lokumisela uxinzelelo oluzenzekelayo | 3-100kg egcwele umda |

| Ubuninzi be-extruder | 250 kg/h |

| I-roller yokupholisa edibeneyo | ∅800×1300 |

| I-Screw Diameter | ∅110mm umlinganiselo35:1 |

| Ubukhulu bedayamitha yokukhulula | ∅1600mm |

| Ubungakanani bokubuyisela umva ubukhulu | ∅1600mm |

| Khulisa undoqo wephepha :3″6″ kwaye Buyisela umqolo idiameter engundoqo:3″6″ | |

| I-Extruder iqhutywa yi-45kw | |

| Amandla onke | malunga nama-200 Kw |

| Ubunzima bomatshini | malunga ne-39000kg |

| Umda wangaphandle | 16110 mm×10500 mm × 3800 mm |

| Umbala womzimba womatshini | Grey kunye noBomvu |

1. Khupha inxalenye (nge-PLC, i-servo ikhulula)

1.1 Khulisa isakhelo

Ulwakhiwo: Isakhelo sokukhulula shaft esingaphantsi kwe-hydraulic

I-BA series splicer yenza inxenye yomgca wokulamanisa kwaye ifakwe phezu kwendawo yokumisa phantsi kwesakhiwo sebhulorho.Ivumela ukuqhubeka ekusebenzeni komqulu wephepha okhoyo ukuya kumqulu wephepha elilandelayo ngaphandle kokumiswa kwemveliso.

Ngaphakathi kwezakhelo zecala le-splicer kukho iintloko ezi-2 ezihambayo kunye necandelo lenkxaso elishukumayo.Ngaphezulu kwayo kukho ii-nip rolls ezi-2.

I-capstan roll, i-reverse idler roll kunye ne-double dancer system yenza icandelo lokuqokelela iphepha elikwaziyo ukuqokelela iphepha ukuya kuma-4 ubude be-splicer.

Umatshini uqhutywa ngephaneli yokusebenza kumatshini

Isantya sokudibanisa iphepha Max.300m/min

a)xa amandla ephepha ngaphezulu kwe-0.45KG/mm, max.300m/mz.

b)xa amandla ephepha ngaphezulu kwe-0.4KG/mm, max.250m/mz.

c)xa amandla ephepha ngaphezulu kwe-0.35KG/mm, max.150m/min;

Ububanzi bephepha

Max.1200mm

Min.500mm

Isantya CE-300

Max.300m/min

Idatha ye-pneumatic

Beka uxinzelelo lwe-6.5 bar

Min.uxinzelelo 6 bar

Umzekelo CE-300

Amandla 3.2kVA, 380VAC/50Hz/20A

Ulawulo lombane 12VDC/24VDC

1.1.1 I-hydraulic shaft spindle spindle clamp arm ezimeleyo yohlobo lwengalo yokusebenzela kabini, ngaphandle kweshaft yomoya, ukulayishwa kwehydraulic, gcina iindleko zokulayisha ubume boomatshini.I-automatic AB shaft auto reel alternation, inkcitho encinci yezinto.

1.1.2 Ubuninzi.uvula idaya.:¢1600mm

1.1.3 Uluhlu lweseto yoxinzelelo oluzenzekelayo: 3-70kg umda ogcweleyo

1.1.4 ukuchaneka koxinzelelo: ± 0.2kg

1.1.5 umxholo wephepha:3”6”

I-1.1.6 Inkqubo yokulawula uxinzelelo: uhlobo lwe-shaft ye-tension detector ngokuchaneka kwe-potentiometer yokufumanisa uxinzelelo, ulawulo oluphakathi lwe-PLC enokucwangciswa.

1.1.7 Inkqubo yokulawula i-Drive: i-PIH cylinder braking, impendulo ye-encoder ejikelezayo ngokukhawuleza, i-valve echanekileyo yokulawula i-valve evaliweyo yokulawula i-loop, isilawuli esicwangcisiweyo se-PLC

1.1.8 Ukusetwa koxinzelelo :Ngoxinzelelo oluchanekileyo olulawula useto lwevalvu

1.2 Ukugcina uhlobo lokukhetha oluzenzekelayo, isixhobo sokusika

1.2.1 Ukugcina okuqhutywa sisithinteli semotor esebenza ngomoya, kuqinisekisa ukuxinana okuzinzileyo xa uchola iphepha.

1.2.2 isakhiwo sokusika esahlukileyo

1.2.3 PLC auto ukubala isantya shaft rotary entsha, kwaye ugcine isantya ngesantya umgca main

1.2.4 Fumana i-roller yokushicilela izinto eziphathekayo, i-cutter ephukileyo yemathiriyeli .tension control change, cwangcisa konke kunokugqiba ngokuzenzekelayo

1.2.5 Ukutshintsha i-alarm yangaphambili yerola,: ububanzi bomsebenzi xa ufikelela kwi-150mm.,

1.3 Ukulawula ukulungiswa: inkqubo yokulawula i-photoelectric putter (isakhiwo se-bst)

2. ICorona (Yilian ilungiselelwe)

Amandla onyango lweCorona :20 kw

3. Iyunithi yokulanyiswa kweHydraulic:

3.1 Iirola ezintathu ze-laminating isakhiwo sekhompawundi, i-back press roller, inokwenza ukuba i-compound roller ibe namandla, iqinile.

3.2 Ukuhluthwa kwe-silicon ye-rubber roller: imveliso edibeneyo kulula ukuyijonga kwi-roller epholileyo, i-Hydraulic inokucinezela ngokuqinileyo.

3.3 Ifilim egobileyo yesakhiwo esicaba,: inokwenza ifilimu isasazwe ngokukhawuleza

3.4 I-compound feed material adjuster roller inokoyisa ubuninzi bezinto zefilimu ezingalinganiyo kunye nobuthathaka

3.5 Isivutheli soxinzelelo oluphezulu lufunxa i-scrap edge ngokukhawuleza.

3.6 Irola yokusika edityanisiweyo

3.7 I-Compound roller iqhutywa yimotor ngokuxhomekeka

3.8 I-Compound roller driven motor ilawulwa yi-Japan frequency controller

Ubalo:

(1) i-roller edibeneyo: ¢ 800 × 1300mm 1pcs

(2) irabha roller: ¢ 260 × 1300mm 1pcs

(3) cofa irola:¢ 300 × 1300 mm 1pcs

(4) ukudibanisa isilinda yeoli:¢63 × 150 2pcs

(5) khulula i-roller: ¢ 130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1iseti

(7) 11KW isiguquli seFrequency (JAPAN YASKAWA)

(8) Jikelezisa isinxibelelanisi: (2.5"2 1.25"4)

4. I-Extruder (ukulungiswa kobude obuzenzekelayo)

4.1 Idayamitha yeScrew:¢ 110,I-Extruder enkulu malunga:250kg/h (iteknoloji yaseJapan)

4.2 T-die (Taiwan GMA)

4.2.1 Ububanzi bokungunda: 1400mm

4.2.2 Ububanzi obusebenzayo bokungunda: 500-1200mm

4.2.3 Umsantsa womlomo wokungunda: 0.8mm, ubukhulu bokugquma: 0.008—0.05mm

4.2.4 Impazamo yokugquma ubukhulu: ≤±5%

4.2.5 Umbhobho wokufudumeza ngombane ngaphakathi kokufudumeza, ukufudumeza okuphezulu okusebenzayo, ubushushu bonyuka ngokukhawuleza

4.2.6 Ipaseji ebiyelwe ngokupheleleyo, Ulungelelwaniso lobubanzi bokugquma

4.3 Izixhobo zothungelwano ezitshintsha ngokukhawuleza

4.4 Ukuhamba ngaphambili nangasemva, kunokuphakamisa ngokuzenzekelayo iTrolley, uluhlu lokuphakamisa :0-100mm

4.5 Mold 7 indawo ulawulo lobushushu.Screw barrel 8 icandelo lokulawula ubushushu.isinxibelelanisi 2 indawo yolawulo lobushushu yamkela iiyunithi zokufudumeza kwe-infrared.

4.6 Ibhokisi yegiya yokuNcitshiswa yamandla amakhulu, AMAZINYO OMKHULU (Guo tai guo mao)

4.7 Isilawuli sobushushu seDijithali solawulo oluzenzekelayo lobushushu

Amalungu aphambili:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW frequency converter (JAPAN YASKAWA)

(3) Umlawuli weqondo lokushisa weDijithali 18pcs

(4) 1.5KW imoto yokuhamba

5.Isixhobo sokucheba imela ye-Pneumatic Round

5.1 Isixhobo sokulungelelanisa i-trapezoidal screw transverse, tshintsha ububanzi bokusika iphepha

5.2 I-Pneumatic Pressure cutter

5.3 5.5kw umngcipheko ophezulu wokufunxa

6.Ukubuyisela umva iYunithi :3D ubume bomsebenzi onzima

6.1 Ukubuyisela umva isakhelo:

6.1.1 Uhlobo lwefriction yombane izikhululo eziphindwe kabini zokubuyisela umva umatshini, ukusika okuzenzekelayo okuhamba ngesantya esiphezulu kunye nokuchola izinto ezigqityiweyo, ukukhulula ngokuzenzekelayo.

6.1.2 Ubuninzi.ukubuyisela umva idayamitha:¢ 1600 mm

6.1.3 isantya sokuqengqeleka: 1r/min

6.1.4 uxinzelelo:3-70kg

6.1.5 Ukuchaneka kweTension: ± 0.2kg

6.1.6 undoqo wephepha: 3″ 6″

6.1.7 Inkqubo yoLawulo lweTension: I-cylinder cushion idada kwisakhiwo sohlobo lwe-roller edadayo, ukunyanzeliswa kubonwa yi-potentiometer echanekileyo, kunye nomlawuli olungelelanisiweyo we-PLC ulawula ukuxhatshazwa.(Japan SMC low friction cylinder) 1 iseti

6.1.8 Inkqubo yokuLawula i-Drive: 11KW i-motor drive, i-rotary encoder speed feedback, i-Senlan AC inverter i-double-closed-loop control control, isilawuli esicwangcisiweyo se-PLC solawulo oluphakathi.Iseti e-1

6.1.9 Ukusetwa kweTension rhoqo: Ukusetwa koLawulo loxinzelelo oluchanekileyo (Japan SMC)

6.1.10 I-Taper tension setting: ibekwe ngokungenasizathu yikhompyutheni yekhompyutheni, ulawulo lwe-PLC, ukuguqulwa ngombane / umlinganiselo womoya (i-Japan SMC)

6.2 Ukutyisa okuzenzekelayo kunye nesixhobo sokusika

6.2.1 I-Splicing Support Rollers ilawulwa yi-PLC ukuqhuba i-motor ukubamba izinto ezikude ne-rubbing roller.

6.2.2 Isixhobo sokusika esiZimeleyo seHydraulic

6.2.3 PLC ubalo oluzenzekelayo lwenkqubo yokukha, ukutshintshwa kwevolumu kugqitywe ngesitshixo.

6.2.4 Umsebenzi wokuXhasa iRola, iMathiriyeli yokuSika, ukuSeta ngokutsha, njl.njl. Kugqitywe ngokuzenzekelayo

6.2.5 Iinkcukacha

(1) I-roller ye-friction: ¢ 700x1300mm 1 ibha

(2) Injini yomoya: 11KW (Shanghai Lichao) iseti e-1

(3) Ukuqengqeleka phantsi kwebhokisi yegiya: lukhuni umphezulu wehelical reducer (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 iseti

(5) Ibhokisi yebhokisi ye-roller yenkxaso: Isethi ye-1 yamandla

(6) I-Speed reducer: izinyo ezinzima 1 iseti yamandla

(7) Isinciphisi sokuhamba ngesantya sokuhamba: Iseti ye-1 yamandla

(8) Ukukhupha isikhululo se-hydraulic

7.I-Auto air shaft puller

8.ICandelo lokuQhuba

8.1 Injini ephambili, ibhanti lokuhambisa lithatha ibhanti ye-synchronous

8.2 Ukudibanisa, ukubuyisela umva kunye nokukhulula i-motor: Ibhanti yokuqhuba ithatha i-arc gear, ikhonkco kunye nokuhanjiswa kwebhanti ehambelanayo

8.3 Ibhokisi yegiya yokuqhuba ephambili: Ukutywina igiya ye-helical entywiliselwe ngeoyile, Umgca we-helical gear transmission structure

9.Iyunithi yoLawulo

Ikhabhinethi yombane ezimeleyo, ulawulo oluphakathi, indawo edibeneyo kunye nokusebenza kwekhabhathi yolawulo oluphakathi.Umatshini wokuzisebenzela ngomatshini usebenzisa isethi ye-PLC (i-hollsys) isixhobo esinamandla okusebenza aphezulu, kunye nemiqondiso yencoko yababini yomatshini kusetyenziswa unxibelelwano lwenethiwekhi phakathi kojongano.I-PLC, iyunithi ye-extrusion, i-man-machine dialogue interface phakathi kwenkqubo yokuqhuba kwaye yenza inkqubo edibeneyo yokulawula ngokuzenzekelayo.Kuba naziphi na iiparameters zingasetwa, ngokubala oluzenzekelayo, inkumbulo, ubhaqo, alarm, njalo njalo. Ngaba tension yesixhobo uboniso olubonakalayo, isantya, ukoleka ubukhulu, isantya kunye nemeko yokusebenza eyahlukileyo.

10. abanye

11.1 I-Roller yesiKhokelo:I-anodization enzima ye-aluminium i-alloy guide roll, inkqubo yentshukumo

11.2 Isixhobo sombane esisezantsi saseFrance Schneider, i-omron yaseJapan, njl.

11.iinxalenye uphawu

11.1 PLC (Beijing Hollysys)

11.2 Isikrini sokuchukumisa (TAIWAN)

I-11.3 isiguquli samaza: eJapan Yaskawa

11.4 Injini engundoqo: SHANGHAI

11.5 isilinda esisezantsi sokukhuhlana (eJapan SMC)

11.6 AC CONTACTOR (Schneider)

11.7 iqhosha (Schneider)

11. Umxubi omileyo (eTaiwan)

11.9 ivalve yokulawula uxinzelelo lwesilinda (Taiwan)

11.10 Ivalve yokutshintshiselana ngemagnethi (Taiwan)

11.11 ivalve yokulawula uxinzelelo oluchanekileyo (SMC)

12.Umthengi ngokwakhe ubonelela ngezibonelelo

12.1 Indawo yezixhobo kunye nesiseko

12.2 Ubonelelo lwezibonelelo zeKhabhinethi yombane yoMatshini

12.3 Ubonelelo lwamanzi kumaziko omatshini ngaphakathi nangaphandle kwesango (umthengi ulungisa isibandisi samanzi)

12.4 Ubonelelo ngerhasi kumatshini osetwe ngaphakathi nangaphandle kwesisu

12.5 Umbhobho wokukhupha umoya kunye nefeni

12.6 Qokelela, ukulayishwa kunye nokothula imathiriyeli esisiseko isixhobo esigqityiweyo

12.7 Ezinye izibonelelo ezingadweliswanga kwikhontrakthi

13. Uluhlu lweendawo ezisetyenzisiweyo:

| Hayi. | Igama | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Umlawuli wobushushu | uOmron |

| 3 | Ivalve yokulawula iMicro | 4V210-08 |

| 4 | Ivalve yokulawula iMicro | 4V310-10 |

| 5 | iswitshi yokusondela | 1750 |

| 6 | Ugqithiso oluqinileyo | 150A kunye ne75A |

| 7 | utshintsho lokuhamba | 8108 |

| 10 | iyunithi yokufudumeza | ϕ90*150mm,700W |

| 11 | iyunithi yokufudumeza | ϕ350*100mm,1.7KW |

| 12 | iyunithi yokufudumeza | 242*218mm,1.7KW |

| 13 | iyunithi yokufudumeza | 218*218mm,1KW |

| 14 | iyunithi yokufudumeza | 218*120mm,800W |

| 15 | Schneider iqhosha | ZB2BWM51C/41C/31C |

| 16 | umoya umqhagi | |

| 17 | Iteyiphu yobushushu obuphezulu | 50mm*33m |

| 18 | itheyiphu yetellon | |

| 19 | Corona roller cover | 200*1300mm |

| 20 | Iphepha lobhedu | |

| 21 | isihluzi sekhusi | |

| 22 | Jikelezisa ii-slits | 150*80*2.5 |

| 23 | isinxibelelanisi sepneumatic | |

| 24 | umpu womoya | |

| 25 | amanzi adibeneyo | 80A kunye ne40A |

| 27 | izikrufu kunye nabanye | |

| 28 | tsala ikhonkco | |

| 29 | ibhokisi yesixhobo |

Amalungu aphambili kunye nomfanekiso:

Unwinder(Auto splicer) → isikhokhelo sewebhu → Umphathi weCorona → Ukwandiswa kunye nenxalenye edibanisa uMda Ukucutha → Ukubuyisela umva